| Sign In | Join Free | My howtoaddlikebutton.com |

|

| Sign In | Join Free | My howtoaddlikebutton.com |

|

| Categories | Flexible PCB Board |

|---|---|

| Brand Name: | Bicheng |

| Model Number: | BIC-305.V1.0 |

| Certification: | UL, ISO9001, IATF16949 |

| Place of Origin: | CHINA |

| MOQ: | 1PCS |

| Price: | USD9.99-99.99 |

| Payment Terms: | T/T |

| Supply Ability: | 5000PCS per month |

| Delivery Time: | 8-9 working days |

| Packaging Details: | Vacuum bags+Cartons |

| Base material: | Polyimide 25μm + 0.3mm stiffener of FR-4 |

| Layer count: | Single side |

| PCB thickness: | 0.2mm |

| PCB size: | 130mm x 15mm = 1 type = 1 piece |

| Solder mask: | Yellow coverlay |

| Silkscreen: | White |

| Copper weight: | Outer layer 35 μm/ Inner layer 0 μm |

| Surface finish: | Immersion gold |

| Company Info. |

| Bicheng Electronics Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

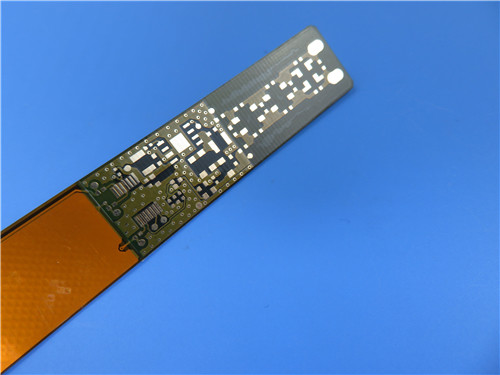

2-Layer Flexible Printed Circuit Board (FPC) Built on Polyimide for Embedded Operating System

(Flexible printed circuits are custom-made products, the picture and parameters shown are just for reference)

General description

This is a type of 2 Layer flexible printed circuit (FPC) built on polyimide for the application of Embedded Operating System.

Basic specifications

Base material: Polyimide 25μm + 0.3mm stiffener of FR-4

Layer count: 2 layers

Type: Individual FPC

Format: 130mm x 15mm = 1 type = 1 piece

Surface finish: Immersion gold

Copper weight: Outer layer 35 μm/ Inner layer 0 μm

Solder mask / Legend: Yellow coverlay / white

Final PCB height: 0.20 mm

Standard: IPC 6012 Class 2

Packing: 100 pieces are packed for shipment.

Lead time: 10 working days

Shelf life: 6 months

Features and benefits

Excellent flexibility;

Reducing the volume;

Weight reduction;

Engineering design prevents problems from occurring in pre-production;

PCB manufacturing is strictly as per required specifications;

Great customer service;

Diversified shipping method: FedEx, DHL, TNT, EMS;

Prototype PCB capability;

Volume Production capability;

Applications

Laser head FPC, Mobile phone battery flex board, medical keypad soft board, LCD module, Industrial control computer soft board, consumer ETC (Electronic Toll Collection ) soft board

Specifications of Standard 1 Layer FCCL

| Specifications | Thickness (µm) | Copper Type | Applications | |

| Polyimide Film | Copper Foil | |||

| SF201 0512SE | 12.5 | 12 | ED | Motor, digital products etc.as univeral connector |

| SF201 0812SE | 20 | 12 | ED | |

| SF201 1012SE | 25 | 12 | ED | |

| SD201 0518SE | 12.5 | 18 | ED | |

| SF201 0818SE | 20 | 18 | ED | |

| SF201 1018SE | 25 | 18 | ED | |

| SF201 0535SE | 12.5 | 35 | ED | automotive electronics etc.. |

| SF201 0835SE | 20 | 35 | ED | |

| SF201 1035SE | 25 | 35 | ED | |

| SF201 1070SE | 25 | 70 | ED | |

| SF201 2070SE | 50 | 70 | ED | Motor, digital products etc.as univeral connector |

| SF201 0512SR | 12.5 | 12 | RA | |

| SF201 0812SR | 20 | 12 | RA | |

| SF201 1012SR | 25 | 12 | RA | |

| SF201 0518SR | 12.5 | 18 | RA | |

| SF201 0818SR | 20 | 18 | RA | |

| SF201 1018SR | 25 | 18 | RA | |

Components of a flexible circuit

A flexible circuit consists of copper foil, dielectric substrate+ coverlay and adhesive.

Copper foil is available in two different types of copper: ED Copper and RA copper.

ED copper is an electro-deposited (ED) copper foil produced in the same way as the copper foil used for rigid printed circuit boards. This also means that the copper is “treated”, i.e., it has a slightly rough surface on one side, which ensures a better adhesion when the copper foil is bonded to the base material.

RA copper is a rolled and annealed copper foil produced from electrolytically deposited cathode copper, which is melted and cast into ingots. The ingots are first hot-rolled to a certain size and milled on all surfaces. The copper is then cold-rolled and annealed, until the desired thickness is obtained.

Copper foil is available in thickness of 12, 18, 35 and 70 μm.

The most common available for dielectric substrate and coverlay is polyimide films. This material can also be used as coverlay. Polyimide is best suited for flexible circuits because of its characteristics as stated below:

High temperature resistance allows soldering operations without damaging the flexible circuits

Very good electrical properties

Good chemical resistance

Polyimide is available in thicknesses of 12.5, 20, 25 and 50 μm.

Base laminates for rigid printed circuit boards are copper foils laminated together with the base materials, the adhesive coming from the prepreg material during lamination. Contrary to this is the flexible circuit where the lamination of the copper foil to the film material is achieved by means of an adhesive system. It is necessary to distinguish between two main systems of adhesive, namely thermoplastic and thermoset adhesives. The choice is dictated partly by the processing, and partly by the application of the finished flexible circuit.

|